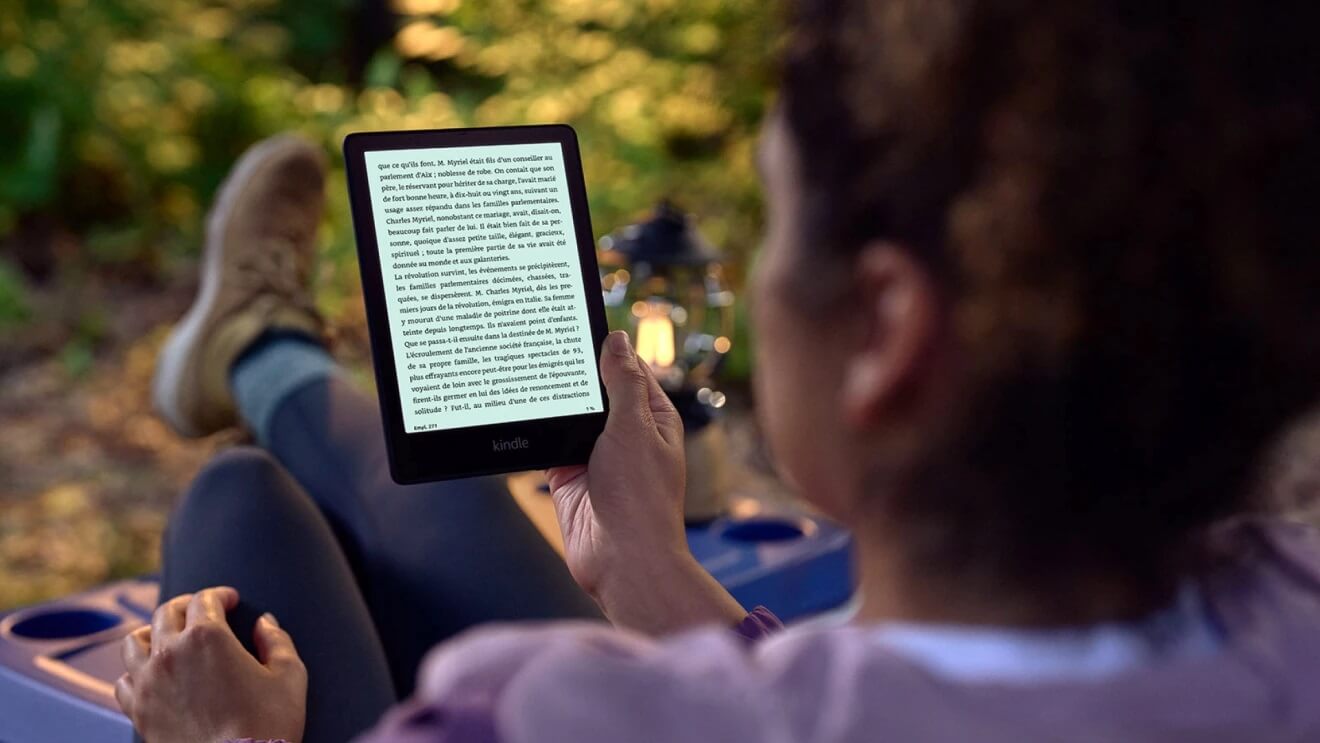

The Kindle is for e-book reading, and Google is for searching online. This should speak volumes about Kindle’s capabilities, not just its scope as a premier e-reader device but also its build quality. We have come across stories of people still enjoying their Kindle devices bought even a decade ago. Such Kindle devices continue to function exceptionally well, save for perhaps depleted battery strength. That’s remarkable, but it is just another day in the office for Amazon.

To be more specific, it is at Lab126 where Amazon has an entire section where men and women toil day in and day out to devise means and methodologies to break a Kindle. The sole purpose of this endeavour is to ensure that only the fittest Kindle reaches the market. Senior hardware reliability engineer Xijia (Erica) Duan leads the efforts, who describes her role at the Amazon facility as putting Kindle prototypes to the most stringent of tests to ensure the most stable and reliable hardware configuration that cuts.

As Duan said in a blog post, their job starts with first assessing the ways users are likely to use their Kindle devices and how the e-readers are likely to be affected in the process. For instance, it might suffer a fall from, say, waist height, be it from the table or when inserted into the bag or pocket. Similarly, chances are that water or coffee gets spilled on it or someone accidentally sits on the Kindle. So, the priority will be to design the Kindle in a manner that can absorb the impact in such cases.

One way to ensure the Kindle is robust is to establish these criteria from the conceptualization and design stage. The next priority is to provide the suitable material for the device’s manufacture. There shouldn’t be any compromise on the quality front, either; otherwise, all efforts to produce a reliable device will fall flat.

Here are the tests the Kindle prototypes must complete before a final design is frozen.

- Quality Materials Testing: Kindle devices are made from high-quality materials. They undergo tests like the four-point bend test to see how much bending force their glass screens can handle. This helps decide which glass is best and how to improve future designs.

- Virtual Testing: Before making physical prototypes, engineers use computer simulations to test how well the Kindle will handle drops and impacts.

- Physical Testing: Once prototypes are made, they’re put through rigorous tests:

- Drop Test: Kindles are dropped from different angles to see how they handle falls on various surfaces.

- Tumble Test: This test simulates the device being tossed around in a machine to see how durable it is from random drops.

- Backpack Test: Mimics the stress of carrying a Kindle in a backpack to ensure it can withstand that pressure.

- Touch Test: Simulates how the device’s touchscreen holds up to repeated touches over its lifetime.

- Twist and Torsion Test: Tests how well the Kindle withstands being bent or twisted, like when packed in a bag.

- Chemical Testing: Checks how Kindle materials react to substances like sunscreen and lotions, ensuring they don’t degrade.

- Solar Exposure Test: Tests how well Kindles resist sunlight exposure without cracking or fading.

- Waterproof Testing: Ensures waterproof Kindles can handle accidental immersion in water.

These tests help ensure that Kindle devices are durable, reliable, and able to withstand the wear and tear of everyday use.

With a keen interest in tech, I make it a point to keep myself updated on the latest developments in technology and gadgets. That includes smartphones or tablet devices but stretches to even AI and self-driven automobiles, the latter being my latest fad. Besides writing, I like watching videos, reading, listening to music, or experimenting with different recipes. The motion picture is another aspect that interests me a lot, and I'll likely make a film sometime in the future.